Variables relating to the functionality of CNC models may possibly vary from one CNC sort to the other. CNC units can be bought in several forms. Almost something starting from lathe systems to water jet models, so the mechanics for each differing machine will be various however, the basic principles do the job mainly for the diverse CNC machine varieties. CNC program ideas actually really should be identified as good elements. The main advantages of a fantastic CNC unit is the similar for just about every single unit as it is for each and every single organization who possesses one particular. Computer program aided technology is an fantastic issue. The CNC technique offers that advantage to their owners. Intervention from the personnel is required much less, though the machine will do all the function as soon as the applications are programmed to the technical specs preferred. The method continues to operate till the job is finished, all totally unmanned. This strategy frees up the personnel to carry out numerous other assignments if needed.

CNC systems provide all these advantages:

A decrease quantity of faults due to the fact of man created slip-up

Continuous machining every single time

Precise machining every time

Decreased manager tiredness, if any whatsoever

Releases the user to do other tasks

Speeds up processing

Reduces misuse

Level of skill to use device is reduced

These are just a number of of the advantages that CNC units have to give you. They supply some other gains that can be primarily based upon the type of CNC machine which is employed.

Transferring out of the production of a single program to the other is really uncomplicated and may possibly save the business considerable time. Previously it could have taken 24 hours to many days to put a machine up in order to make the right cuts that are necessary for your order. At present, with the CNC machines, arrange time is significantly reduced. It actually is just about as quick as running a diverse application.

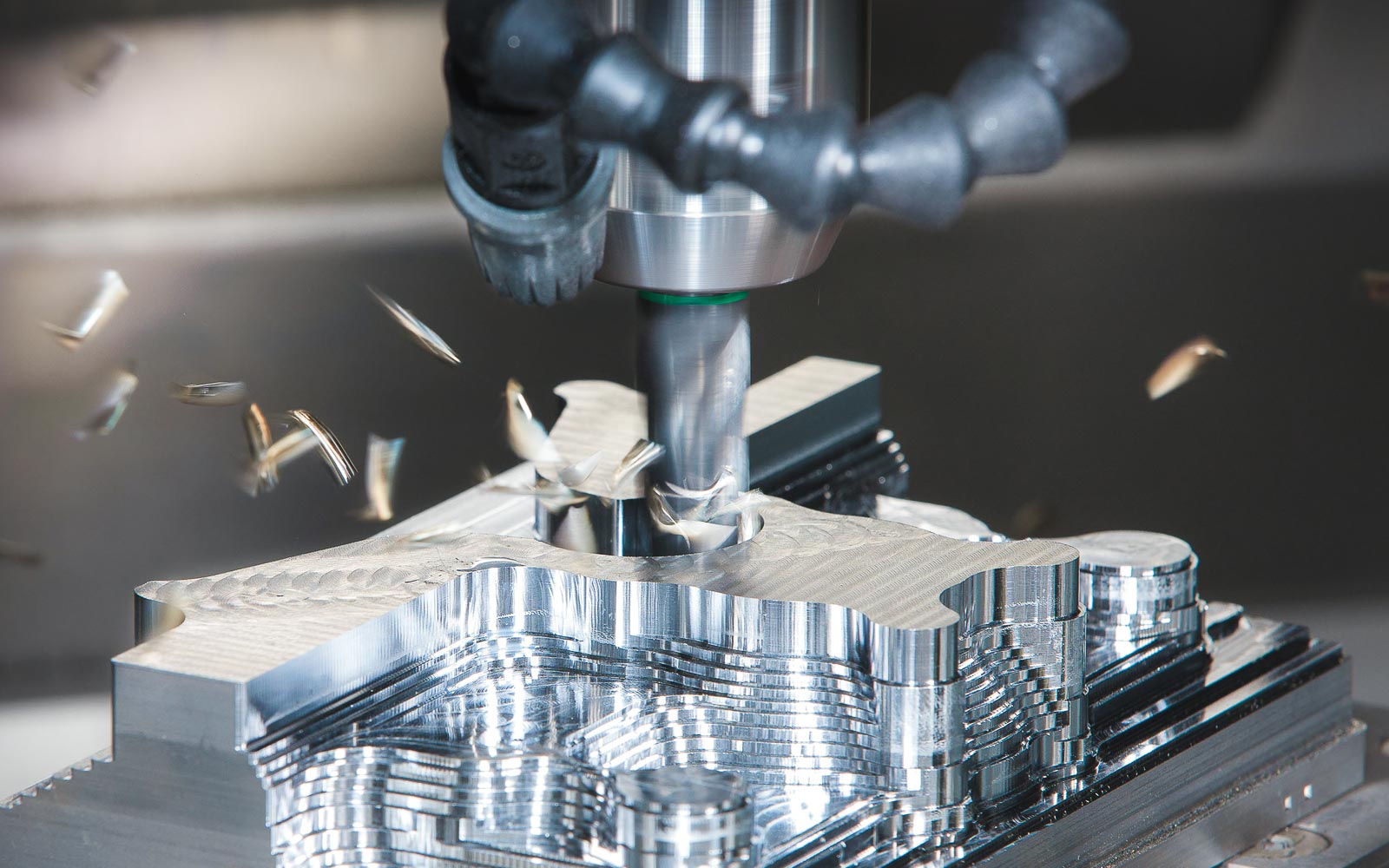

CNC devices (like CNC Shark) run not just via a programs, they are action manipulated and operated with lots of distinct axes depending upon the type of the machine. The CNC lathe program operates on the X plus Y axis not like the five axis devices which you’ll come across now readily available in the marketplace. The higher amount of axes that your unit is run on, the additional delicate and precise the cuts. Extra original you are able to turn out to be in your assignments, and also the a lot more you happen to be able to present fabrication services. The CNC systems can just about do it all with out getting individuals involvement apart from by means of the use of the pc system.

CNC Shark is going to make your personal function simple and hunting impressive. At CNC Spindle Manufacturer , the computer system, by way of the laptop computer software, instructs the machine on what precisely to get accomplished and also the machine is continuously on the function till the technical specs or recommendations are already reached, upon which time it stops approach towards the sheet of material. The human involvement that is necessary along with a CNC device is the programming. Programming for any units is typically written in word such as structures which are in code. The code informs the different axes what path to go and also totally manages every single aspect of the method.